Home Total Quality Management System

Total Quality Management is a "management philosophy" and a "strategic approach".

Certainly, here is a comprehensive overview of the **Total Quality Management (TQM) system**:

### **What is Total Quality Management?**

Total Quality Management is a **management philosophy** and a **strategic approach** that encompasses the entire organization, aiming to achieve long-term success by achieving customer satisfaction and engaging all members of the organization in the continuous improvement process of quality in all products, processes, and services.

In other words, it's not just an isolated "quality program," but a culture adopted by management and spread among all employees to continuously improve performance.

---

### **Basic Principles of Total Quality Management**

Total Quality Management is based on several interconnected basic principles:

1. **Customer Focus:** * The ultimate goal is to meet and exceed customer expectations. They are not only external customers but can also be internal customers (such as an employee in a department considering his colleague in the next department as his internal customer).

2. **Continuous Improvement (Kaizen):** * It is the core of Total Quality Management. It means constantly seeking ways to perform work better, whether it's small incremental improvements or large innovative leaps. The most famous methodology is the **PDCA** Cycle (Plan - Do - Check - Act).

3. **Total Employee Involvement:** * Quality is not limited to the quality control team. All employees at all levels must be empowered and involved in the improvement process. This requires continuous training, creating work teams, and solving problems.

4. **Strategic and Visionary Leadership:** * Top management must adopt and lead the TQM philosophy. The role of leadership is to create the vision, set goals, and provide a supportive environment and the necessary resources for success.

5. **Process-Centered Approach:** * TQM focuses on improving **processes** not just inspecting **outputs**. The idea is that if processes are improved, results will automatically improve.

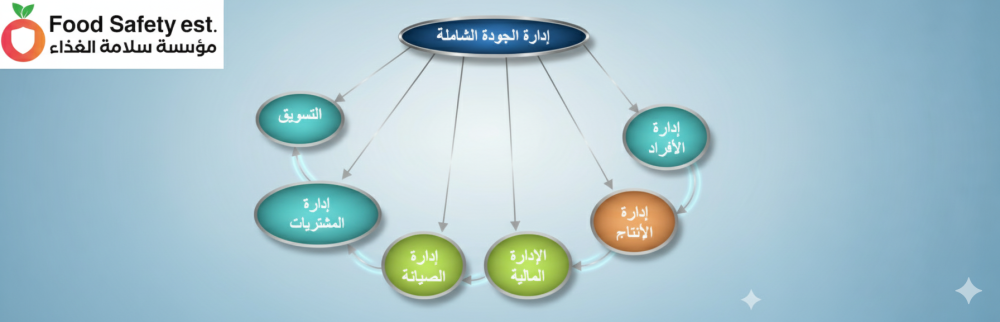

6. **Systematic Approach:** * Viewing the organization as an integrated system of interconnected processes. No part can be improved in isolation from others; integration between departments is critical.

7. **Fact-Based Decision Making:** * Using data and information (such as statistics and performance metrics) to analyze performance and make decisions, rather than relying on intuition or opinions alone.

---

### **Tools and Techniques of Total Quality Management**

There are many tools used to apply the principles of Total Quality Management, including:

* **Cause-and-effect diagram (Fishbone diagram).*** **Pareto Chart.*** **Statistical Control Charts.*** **Quality Audits.*** **Customer Satisfaction Metrics.*** **Process Performance Metrics.**

---

### **Benefits of Implementing Total Quality Management**

* **Improve product and service quality** and reduce errors and defects.* **Increase customer satisfaction** and loyalty.* **Boost employee morale** and increase productivity due to their involvement.* **Reduce costs** by minimizing waste and rework.* **Improve efficiency and productivity** in processes.* **Enhance competitive advantage** in the market.* **Create a positive organizational culture** based on collaboration and improvement.

---

### **Challenges of Implementing Total Quality Management**

* **Insufficient commitment from top management.*** **Resistance to change** from employees or middle management.* **Unrealistic expectations** that results will be immediate.* **Lack of adequate training** or necessary resources.* **Difficulty in changing prevailing organizational culture.**

In conclusion, Total Quality Management is not a magical solution or a temporary program, but a continuous journey that requires long-term commitment and investment in people and processes. When applied correctly, it transforms the organization into a more resilient, efficient, and capable entity to survive and compete in the global market.